Good machinability & formability

BRASS

CW508L

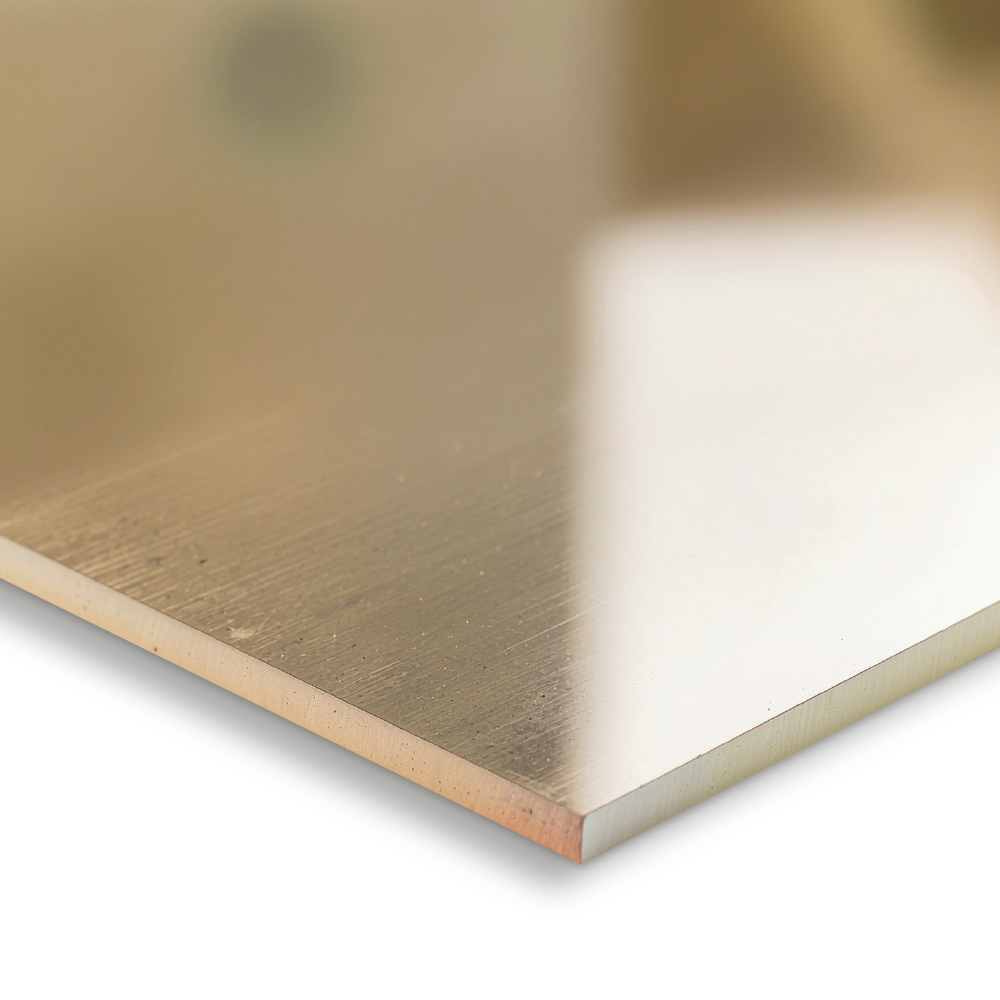

Mill finished

Brass CW508L is a versatile copper–zinc alloy known for its good corrosion resistance, excellent formability and reliable machinability. Supplied with a mill-finished surface, it has a smooth, even appearance with a natural yellow-gold tone suitable for both functional and decorative applications.

Available thicknesses:

Corrosion resistant alloy

1 mm · 3 mm

Mill-finished brass surface

WHAT CAN I MAKE WITH BRASS CW508L?

✔ DECORATIVE & DESIGN COMPONENTS

Why? Natural brass colour provides a distinctive visual appearance.

Examples: Panels, trims, decorative plates, interior details.

✔ ELECTRICAL & TECHNICAL COMPONENTS

Why? Good electrical conductivity and corrosion resistance.

Examples: Contact plates, technical fittings, conductive parts.

✔ ARCHITECTURAL & INTERIOR APPLICATIONS

Why? Smooth surface suitable for visible installations.

Examples: Wall panels, cladding details, design elements.

✔ FURNITURE & CUSTOM METAL WORK

Why? Combines workability with an attractive finish.

Examples: Furniture details, fittings, custom metal components.

✔ GENERAL FABRICATION & SHEET METAL PARTS

Why? Easy to process and reliable material behaviour.

Examples: Plates, brackets, bent parts.

✔ LASER-CUT BRASS PARTS

Why? Clean cutting results with consistent surface quality.

Examples: Laser-cut panels, custom shapes, precision parts.

Brass CW508L is commonly used in applications where formability, corrosion resistance and an attractive metallic appearance are important.

Easily order your Brass CW508L with Scandcut!

We offer laser cutting, bending, deburring, tapping and powder coating for Brass CW508L parts. Upload your CAD file to get instant pricing online!

BRASS CW508L FAQ’s

-

1 mm · 3 mm

-

Brass CW508L parts can be supplied with additional processing such as bending, deburring, tapping and powder coating.

All available options are selected directly in the online configurator after uploading your CAD file!