Plastics

Explore our range of plastic materials available for laser & water cutting, bending and tapping.

Upload your CAD file to receive instant pricing, 100% online!

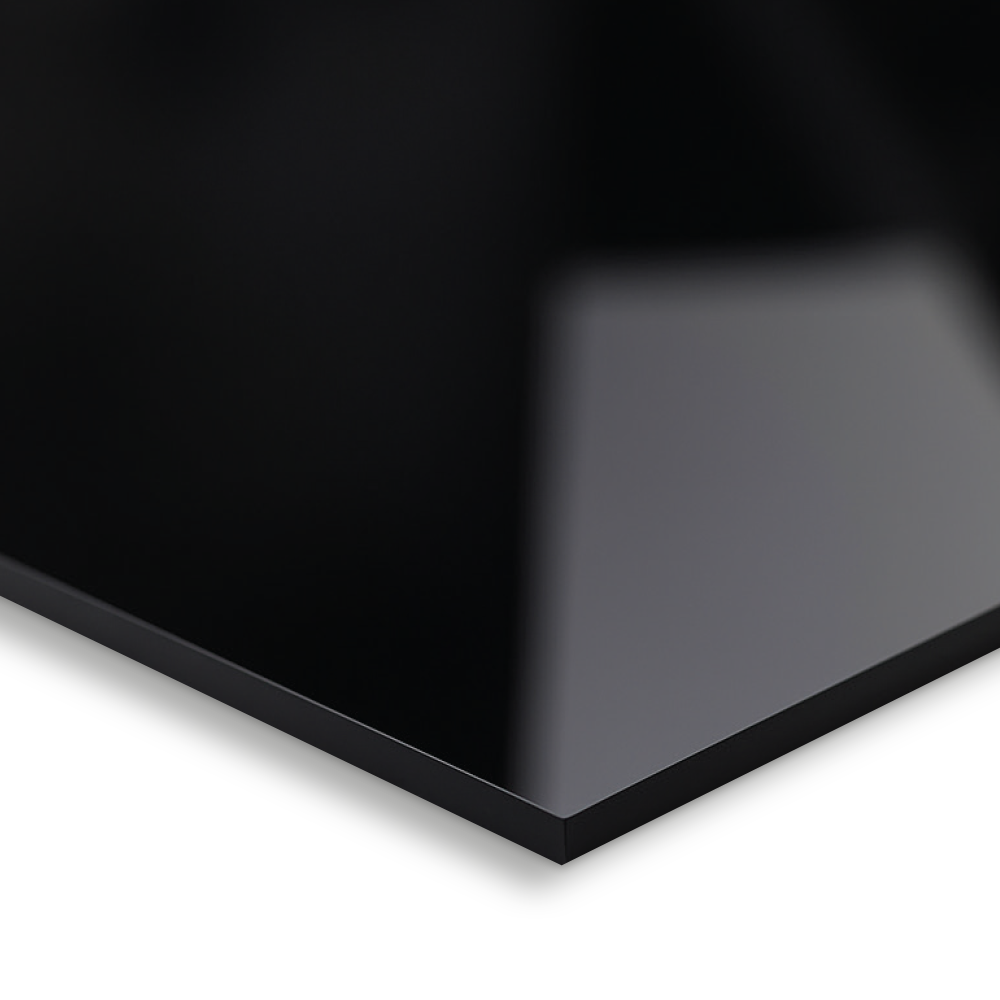

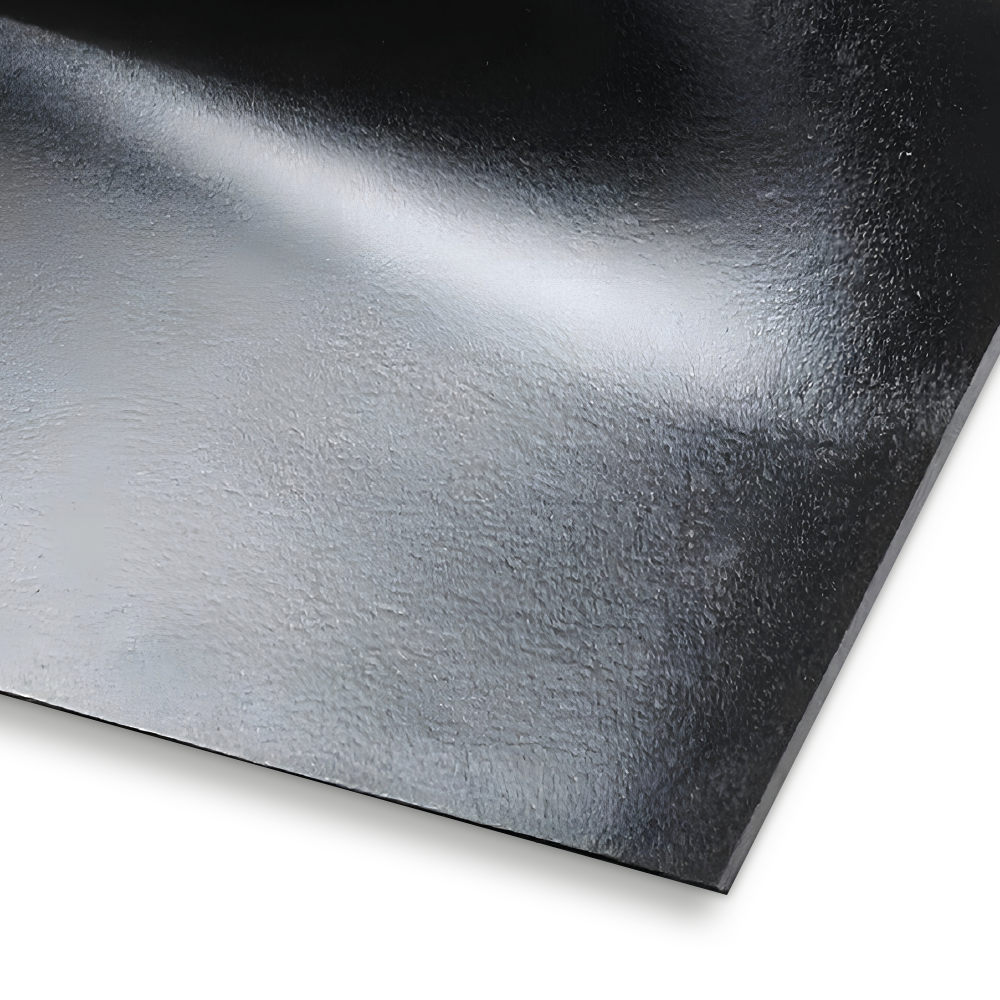

Acrylic - Black

Rigid thermoplastic PMMA / Plexiglass

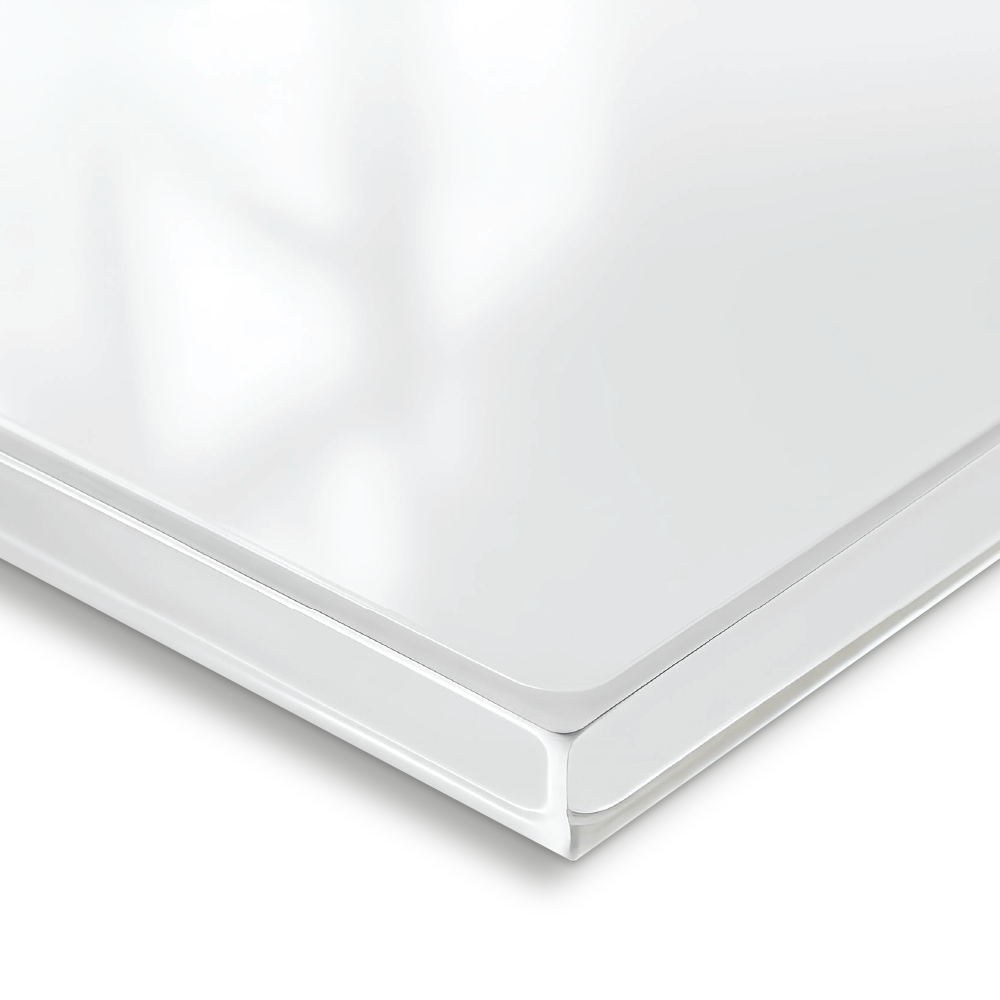

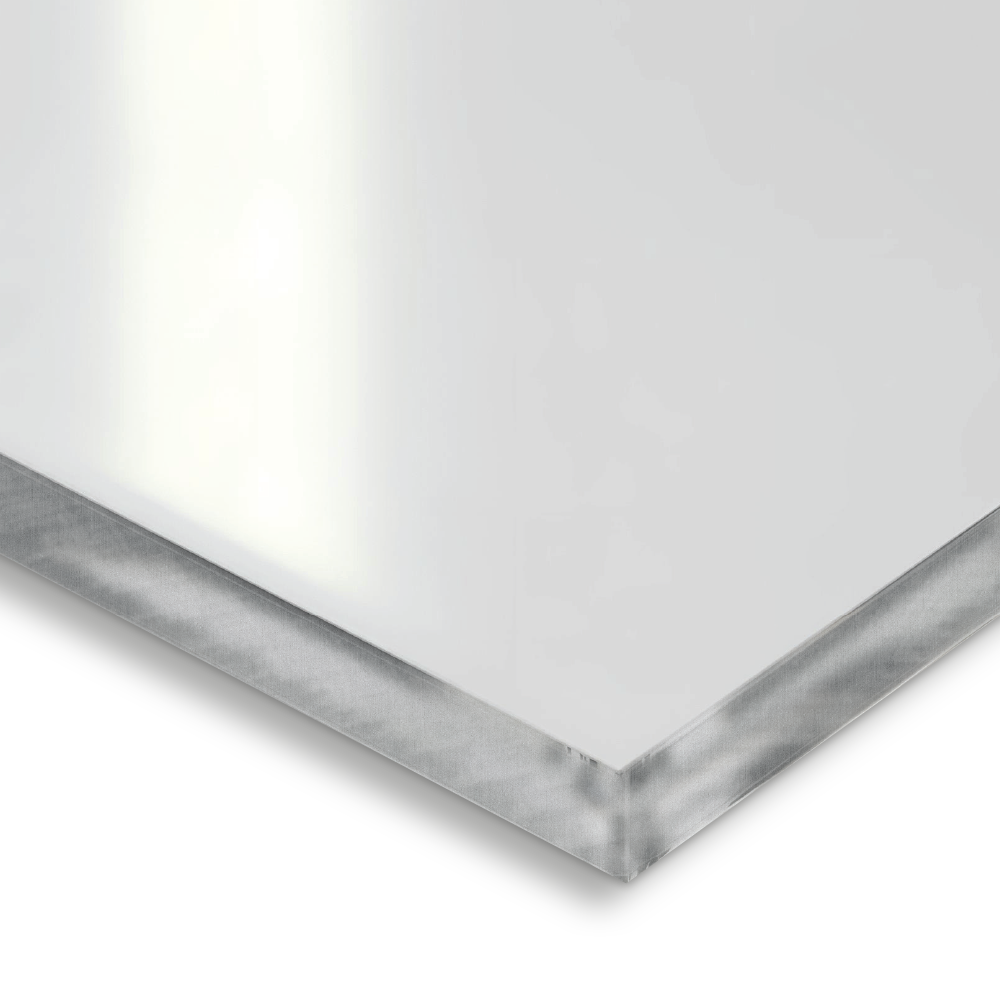

Acrylic - Clear

Rigid thermoplastic PMMA / Plexiglass

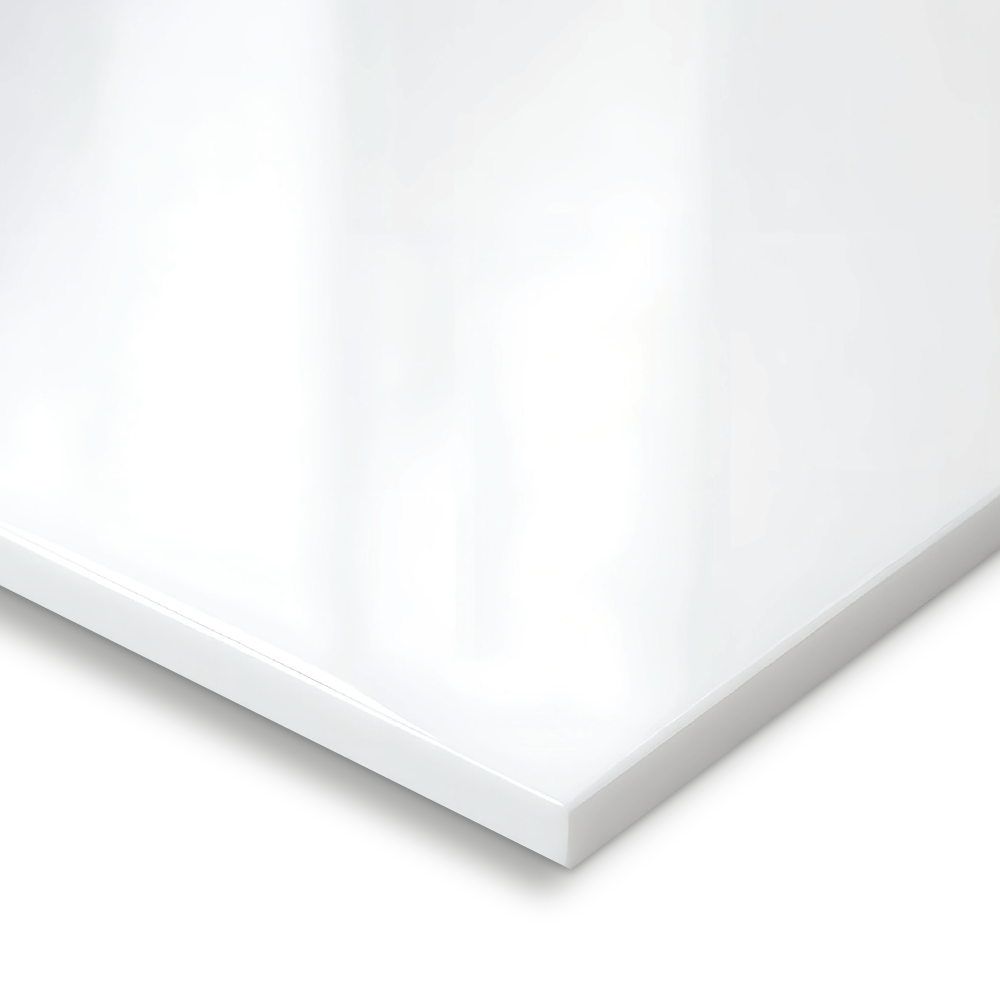

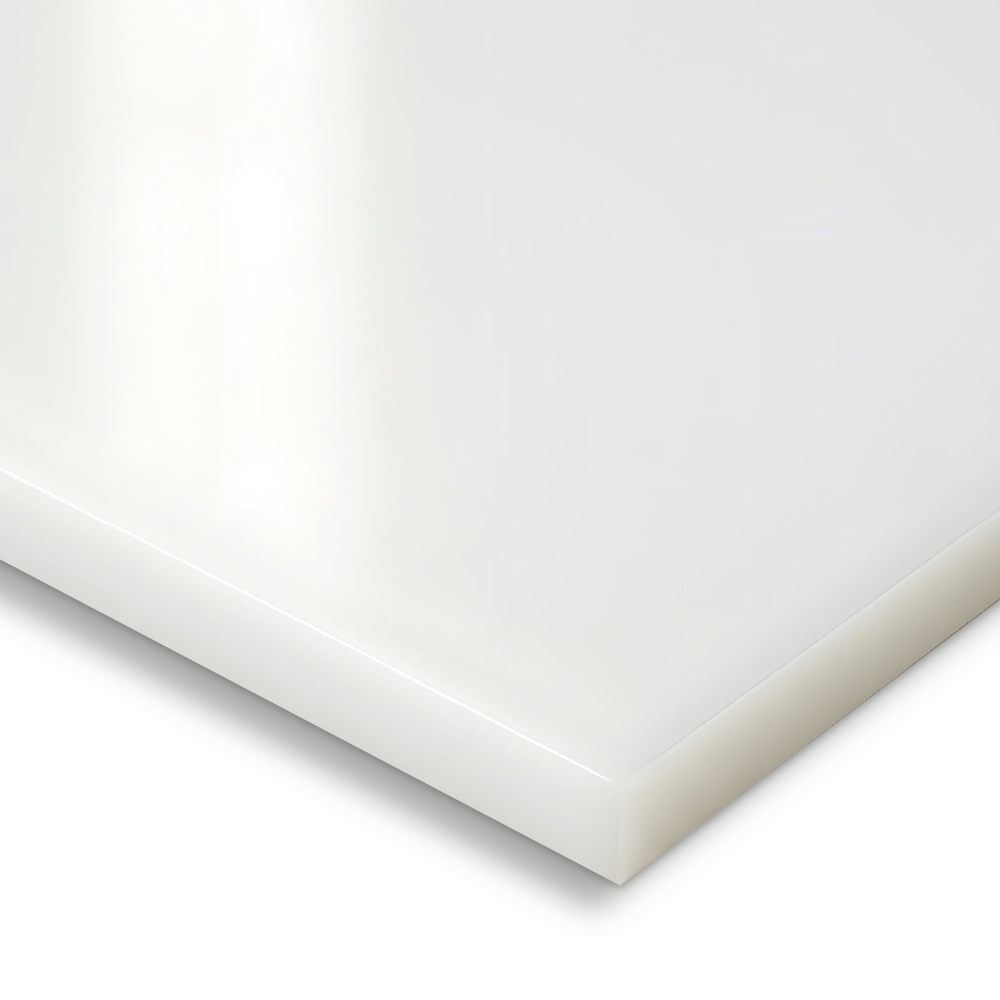

Acrylic - White

Rigid thermoplastic PMMA / Plexiglass

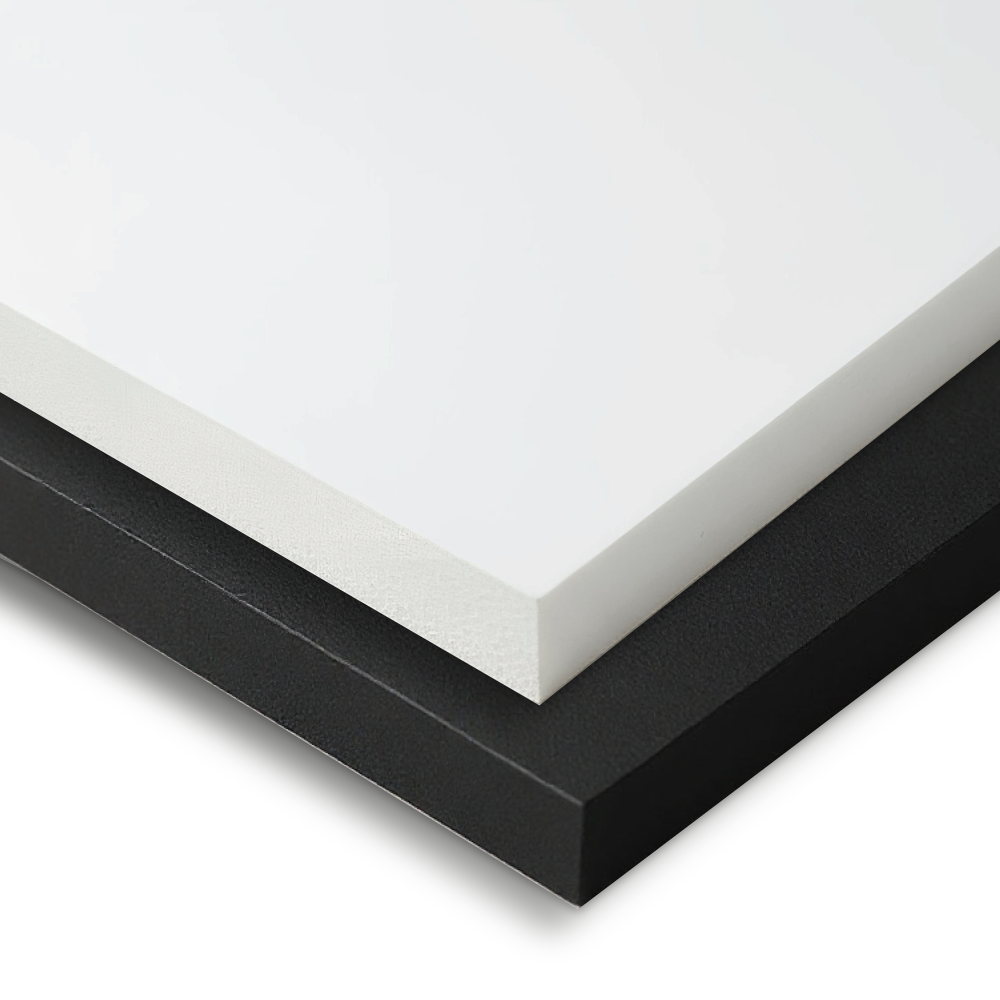

FOREX® - White/Black

High-quality foamed PVC sheet

Nitrile Rubber

Flexible synthetic rubber material

Polycarbonate

Exolon® High-performance thermoplastic

Polyethelene

Rigid thermoplastic PMMA / Plexiglass

Upload your CAD file – instant price!

With our advanced online service you can easily combine lasercutting, water-jet cutting, bending, tapping and powdercoating for a complete product, fast and hassle-free!