1/2 hard temper

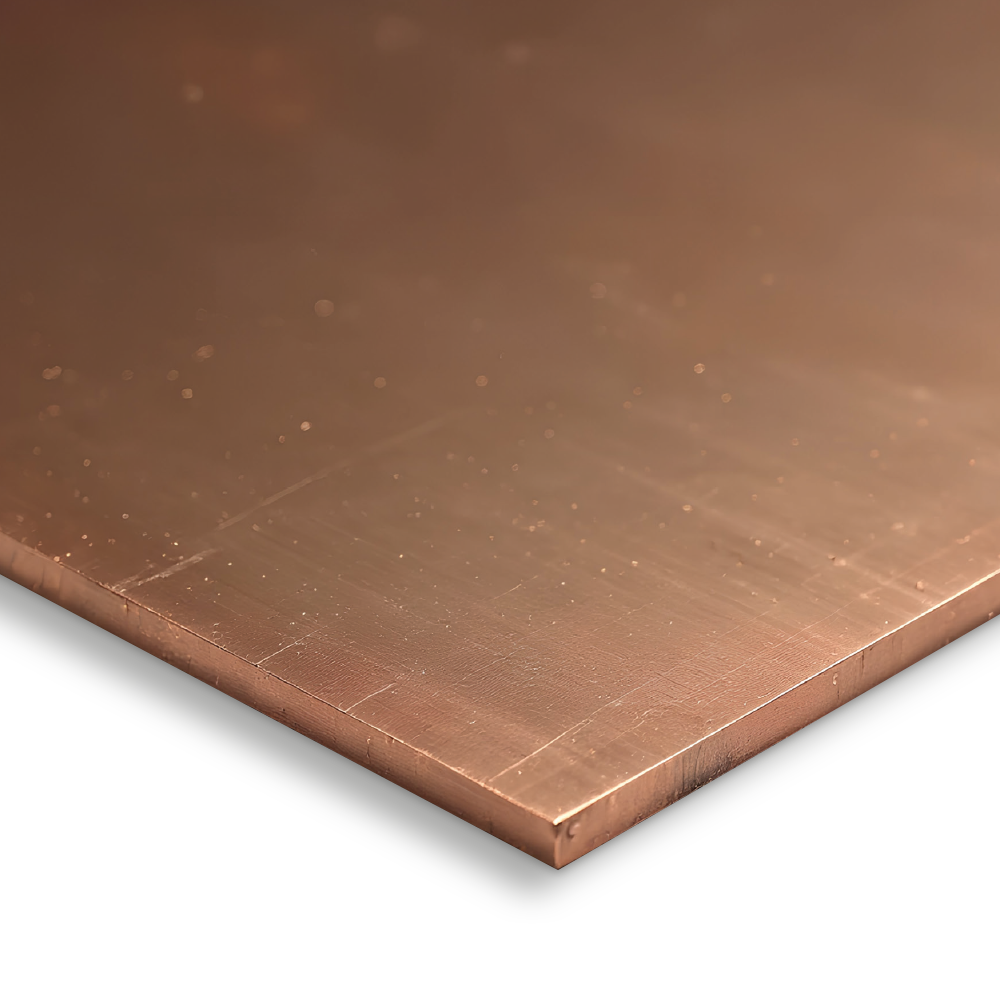

COPPER

CW024A – 1/2 Hard

Copper CW024A is a high-purity copper grade known for its excellent electrical and thermal conductivity. Supplied in 1/2 hard condition, it offers increased strength compared to soft copper while maintaining good workability for technical and industrial applications.

Available thicknesses:

Excellent electrical conductivity

0,6 mm

High thermal conductivity

WHAT CAN I MAKE WITH COPPER CW024A?

✔ ELECTRICAL COMPONENTS

Why? Excellent electrical conductivity with added stiffness.

Examples: Busbars, contact plates, conductive parts.

✔ INDUSTRIAL ELECTRICAL INSTALLATIONS

Why? Reliable performance in power and control systems.

Examples: Electrical panels, grounding components.

✔ THERMAL MANAGEMENT PLATES

Why? High thermal conductivity enables efficient heat dissipation.

Examples: Heat spreaders, cooling plates, thermal components.

✔ CUSTOM LASER-CUT COPPER PARTS

Why? Clean cutting with consistent material properties.

Examples: Laser-cut conductive shapes, custom profiles.

✔ TECHNICAL SHEET-METAL PARTS

Why? 1/2 hard temper provides better shape retention.

Examples: Plates, covers, precision parts.

✔ SPECIALIST FABRICATION PROJECTS

Why? High-purity copper for demanding technical requirements.

Examples: Prototypes, specialised components, custom parts.

Copper CW024A in 1/2 hard condition is typically used in applications that require high conductivity combined with increased mechanical strength.

Easily order your Copper CW024A with Scandcut!

We offer laser cutting, bending, deburring, tapping and powder coating for Copper CW024A parts. Upload your CAD file to get instant pricing online!

COPPER CW024A FAQ’s

-

0,6 mm

-

Copper CW024A parts can be supplied with additional processing such as bending, deburring, tapping and powder coating.

All available options are selected directly in the online configurator after uploading your CAD file!