Designed for outdoor use

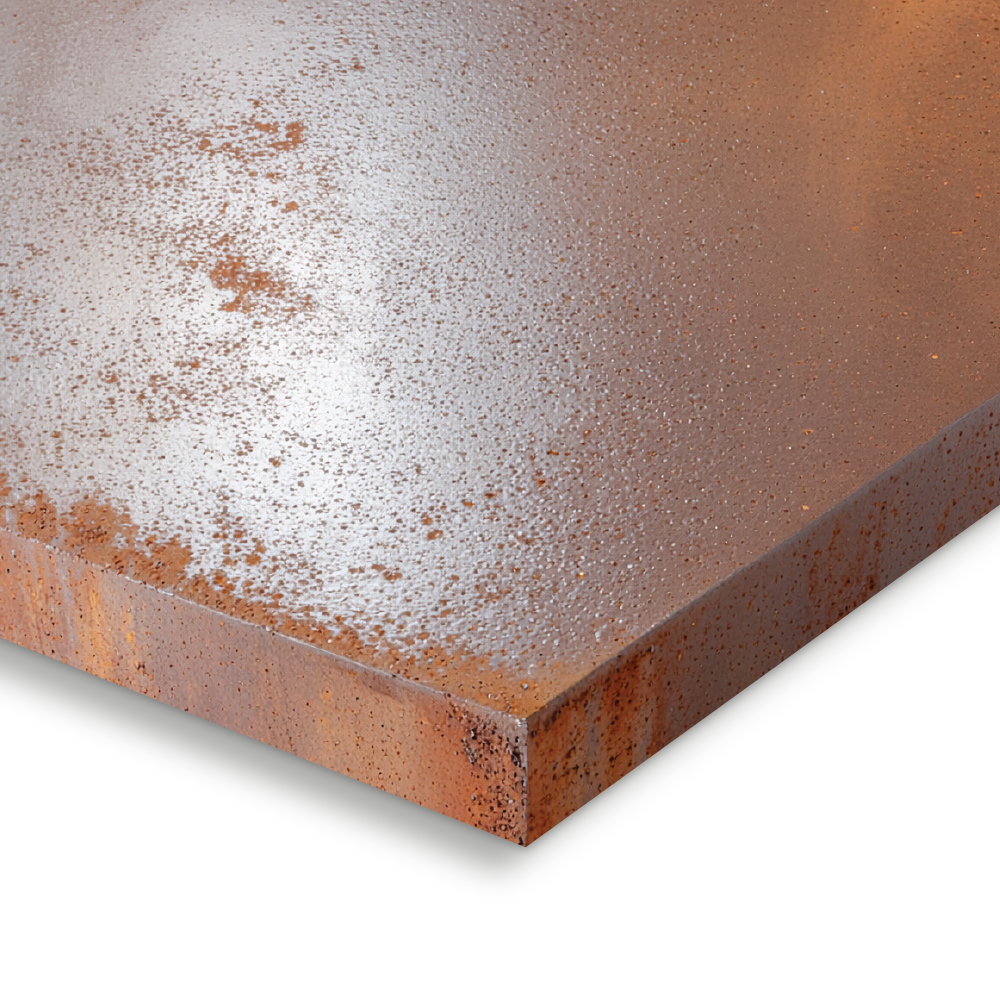

CORTEN STEEL

(COR-TEN)

Corten steel, also known as COR-TEN steel, is a weathering steel designed to form a protective rust-like surface when exposed to the elements. This natural patina protects the steel from further corrosion while giving it a distinctive and architectural appearance.

Available thicknesses:

Self protecting surface

1 mm · 2 mm · 3 mm · 4 mm · 5 mm

Distinctive appearance

WHAT CAN I MAKE WITH CORTEN STEEL

✔ ARCHITECTURAL FACADES & CLADDING

Why? Evolving surface while resisting atmospheric corrosion.

Examples: Building façades, wall cladding, exterior panels.

✔ URBAN FURNITURES & STRUCTURES

Why? Durable steel for exposed public environments.

Examples: Benches, screens, shelters, signage structures.

✔ OUTDOOR LANDSCAPING & DESIGN ELEMENTS

Why? Natural weathering creates low-maintenance surface.

Examples: Planters, edging, retaining walls, garden features.

✔ INDUSTRIAL & INFRASTRUCTURE APPLICATIONS

Why? Designed to withstand harsh atmospheric conditions.

Examples: Bridges, structural panels, exposed steel components.

✔ PUBLIC ART & SCULPTURES

Why? Aesthetic surface that changes character over time.

Examples: Sculptures, monuments, installations.

✔ CUSTOM FABRICATED OUTDOOR PARTS

Why? Can be cut and formed while retaining weathering properties.

Examples: Laser-cut panels, folded parts, decorative steel elements.

Corten steel is widely used in applications where both durability and visual expression are important, particularly in outdoor and architectural projects.

Easily order your Corten steel with Scandcut!

We offer laser cutting, bending, deburring, tapping and powder coating for Corten Steel parts. Upload your CAD file to get instant pricing online!

CORTEN STEEL FAQ’s

-

1 mm, 2 mm, 3 mm, 4 mm, 5 mm

-

Corten steel parts can be supplied with additional processing such as bending, deburring, tapping and powder coating.

All available options are selected directly in the online configurator after uploading your CAD file!