For demanding environments

⬇ DOWNLOAD DATASHEET (PDF)

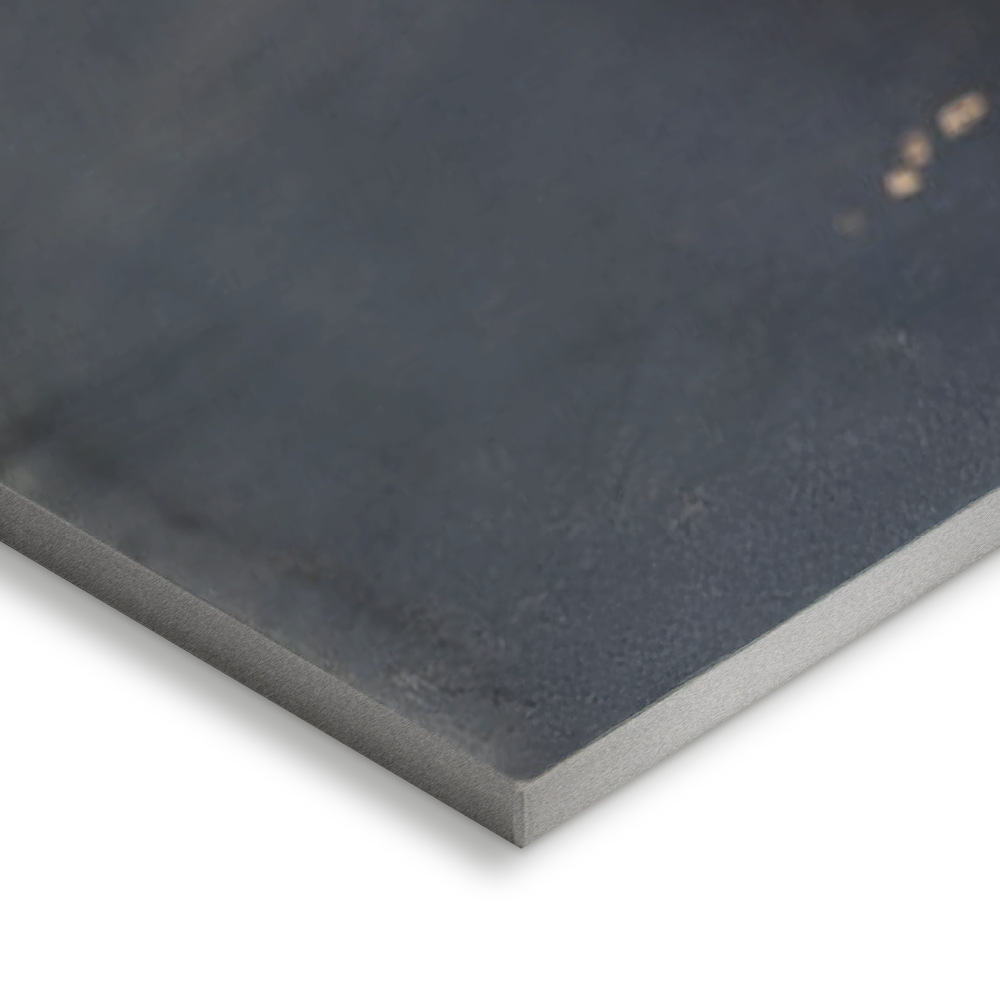

HARDOX®

HB 450 WEAR PLATE

Hardox® HB 450 is a high-performance wear-resistant steel plate designed for demanding applications exposed to abrasion and mechanical stress. It offers an excellent combination of hardness, strength and toughness, making it suitable for long service life in harsh environments.

Available thicknesses:

High strength & toughness

3 mm · 4 mm · 5 mm · 6 mm

8 mm · 10 mm · 12 mm · 16 mm · 20 mm

Exceptional wear resistance

WHAT CAN I MAKE WITH HARDOX® HB 450?

✔ WEAR PLATES & LINERS

Why? Extremely high resistance to abrasion extends service life.

Examples: Liners, wear plates, protective steel panels.

✔ AGRICULTURAL MACHINERY

Why? Withstands wear from soil, gravel & organic material.

Examples: Plough components, spreader parts, protective guards.

✔ MINING & QUARRY EQUIPMENT

Why? Designed to handle continuous abrasion and impact.

Examples: Chutes, hoppers, screens, dump bodies.

✔ INDUSTRIAL MATERIAL HANDLING

Why? Reduced wear lowers maintenance and downtime.

Examples: Conveyors, transfer points, handling systems.

✔ CONSTRUCTION & EARTH MOVING EQUIPMENT

Why? High hardness combined with structural strength.

Examples: Buckets, blades, side plates, reinforcement parts.

✔ HEAVY DUTY FABRICATED COMPONENTS

Why? Can be cut and formed while retaining wear properties.

Examples: Laser-cut wear parts, bent plates, custom components.

Hardox HB 450 is commonly used in applications where high resistance to wear, impact and mechanical stress is critical.

Easily order your HARDOX® HB 450 with Scandcut!

We offer laser cutting, bending, deburring, tapping and powder coating for HARDOX® parts. Upload your CAD file to get instant pricing online!

HARDOX® HB 450 FAQ’s

-

3 mm · 4 mm · 5 mm · 6 mm · 8 mm · 10mm · 12 mm · 16 mm · 20 mm

-

Hardox HB 450 parts can be supplied with additional processing such as bending, deburring, tapping and powder coating.

All available options are selected directly in the online configurator after uploading your CAD file!