Good formability & weldability

STAINLESS STEEL

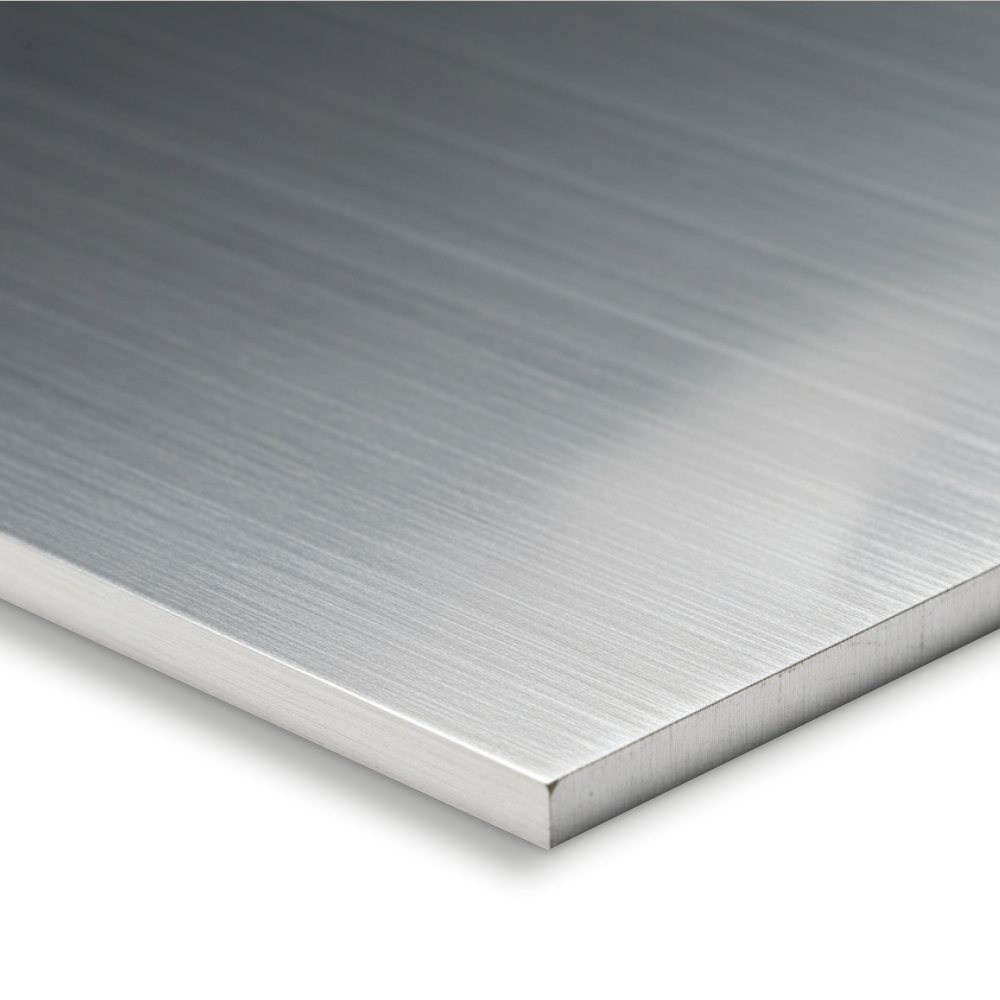

4301 - 2B FINISH

Stainless Steel 4301 is an austenitic stainless steel grade known for its excellent corrosion resistance, good mechanical properties and versatility. Supplied with a 2B finish, it features a smooth, matte surface with a uniform grey appearance, suitable for both functional and visible applications.

Available thicknesses:

Excellent corrosion resistance

0,5 mm · 0,7 mm · 1 mm · 1,5 mm · 2 mm · 3 mm

4 mm · 5 mm · 6 mm · 8 mm · 10 mm · 12 mm

15 mm · 20 mm

Smooth 2B surface finish

WHAT CAN I MAKE WITH STAINLESS STEEL 4301?

✔ INDUSTRIAL HOUSING & ENCLOSURES

Why? Corrosion-resistant steel with a clean, uniform surface.

Examples: Electrical cabinets, machine housings, protective covers.

✔ MEDICAL & LABORATORY COMPONENTS

Why? Clean surface and resistance to cleaning agents.

Examples: Equipment panels, covers, structural parts.

✔ FOOD & PROCESSING EQUIPMENT

Why? Hygienic surface and good corrosion resistance.

Examples: Panels, covers, work surfaces, processing components.

✔ GENERAL STAINLESS STEEL FABRICATION

Why? Balanced mechanical properties and easy processing.

Examples: Brackets, plates, bent parts, welded assemblies.

✔ ARCHITECTURAL & INTERIOR APPLICATIONS

Why? Neutral matte finish suitable for visible installations.

Examples: Wall panels, trims, interior cladding.

✔ CUSTOM LASER-CUT PROJECTS

Why? Smooth 2B finish straight from material supply.

Examples: Laser-cut panels, backplates, functional components.

Stainless Steel 4301 with 2B finish is widely used in applications that require corrosion resistance, clean appearance and reliable fabrication properties.

Easily order your Stainless Steel 4301 with Scandcut!

We offer laser cutting, bending, deburring, tapping and powder coating for Stainless Steel 4301 parts. Upload your CAD file to get instant pricing online!

STAINLESS STEEL 4301 FAQ’s

-

0,5 mm · 0,7 mm · 1 mm · 1,5 mm · 2 mm · 3 mm · 4 mm · 5 mm · 6 mm · 8 mm · 10 mm · 12 mm · 15 mm · 20 mm

-

Stainless Steel 4301 parts can be supplied with additional processing such as bending, deburring, tapping and powder coating.

All available options are selected directly in the online configurator after uploading your CAD file!