Good corrosion resistance

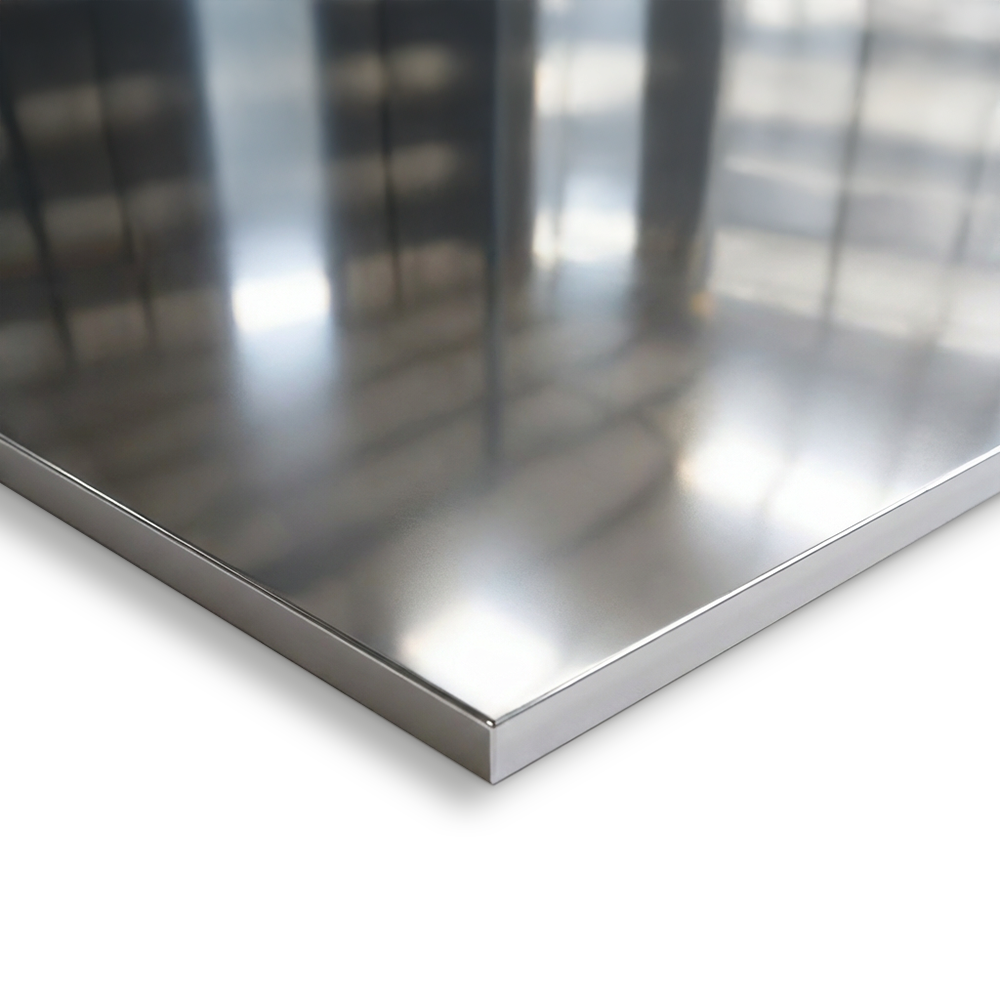

STAINLESS STEEL

EN 4307 2R

BRIGHT ANNEALED

Aluminium EN AW-6082 is a high-strength, heat-treatable aluminium alloy commonly used for structural and load-bearing applications. It offers an excellent balance of strength, machinability and corrosion resistance for demanding industrial use.

Available thicknesses:

Premium 2R surface

1 mm · 1,5 mm · 2 mm

Good machinability

WHAT CAN I MAKE WITH STAINLESS STEEL EN 4307 2R?

✔ DESIGN & INTERIOR

Why: Bright, uniform surface with strong visual appeal.

Examples: Interior panels, decorative components, visible details.

✔ PRECISION SHEET METAL

Why: Excellent laser cut quality and dimensional accuracy.

Examples: Laser-cut components, thin precision parts.

✔ KITCHEN & FOOD APPLICATIONS

Why: Hygienic, corrosion-resistant, and easy to clean.

Examples: Covers, splash guards, kitchen components.

✔ ARCHITECTURAL DETAILS

Why: Reflective surface that maintains its appearance over time.

Examples: Visible façade elements, design panels.

✔ MEDICAL & ELECTRONICS

Why: Smooth surface, chemical resistance, and precision.

Examples: Housings, front panels, technical enclosures.

✔ GENERAL SHEET METAL WORK

Why: Easy to process while maintaining surface finish.

Examples: Bent parts, brackets, custom components.

Stainless steel EN 4307 2R is commonly used in applications that require high surface quality, good corrosion resistance, and precise processing.

Easily order your Stainless Steel EN 4307 2R parts online.

We offer laser cutting, water cutting, bending, deburring, tapping and powder coating for Stainless Steel EN 4307 2R parts. Upload your CAD file to get instant pricing online!

Stainless Steel EN 4307 2R FAQ’s

-

1 mm, 1,5 mm, 2 mm

-

Stainless Steel EN 4307 2R parts can be supplied with additional processing such as bending, deburring, tapping and powder coating.

All available options are selected directly in the online configurator after uploading your CAD file!